Use Case: Pontiradio

Mobile All-in-One-Solution

Saving costs through safety

THIS USE CASE IS ALSO AVAILABLE AS PDF-FILE

Download use case

Task

A large oil company in Italy commissioned the renowned institute L‘Istituto di Vigilanza dell‘Urbe (IVU) to optimize and secure the refuelling of petrol tanks at gas stations. This posed a challenge due to the high safety measures for the refuelling process.

Delivery and filling, for example, may only be carried out by specialized forwarding agents, under the supervision of a qualified person. In this case, every truck driver had to be accompanied by a supervisor in order to provide help quickly in case of an emergency. A good precaution, but not efficient.

Purpose

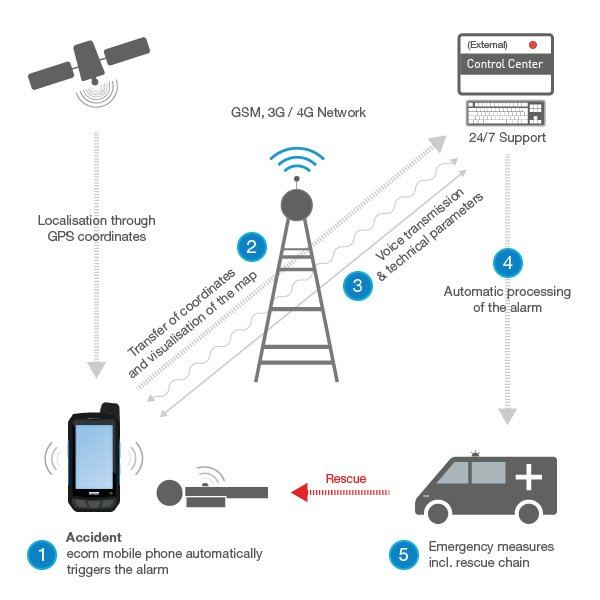

Therefore, the aim was to centralise the monitoring of tank processes in a control centre and to implement a comprehensive protection system for the single worker. To achieve this, the solution needed to meet high safety and communication requirements:

- Explosion-proof, zone 1/21 ATEX certified

- Real-time communication between the individual operator and the control room

- Remote monitoring using real-time video streaming

- Control of single worker protection from the control room

- Automatic notification on entry and exit from the work areas

- Control of the terminal (battery level, activation of GPS....)

- Log all data on a single server for analysis and reporting

Advantages

Where previously two people (truck driver and supervisor) were necessary for safety, one driver is now sufficient. The supervisor no longer has to be on site, because the devices are monitored continuously (GPS position, battery charge, signal quality, connection status) and entries and exits in a filling station are automatically noted. Therefore, he can focus on his main activities (safety inspection, control of PPE, emergency management). This is an enormous boost for productivity and safety in operation. Within seconds, the supervisor in the control room can determine whether an alarm is real and alert the emergency service. It is also possible to document an emergency situation by using recorded voice communication, video streaming, GPS position and event logs.

Solution

This solution met the high requirements and functioned as a technological basis for the networked applications. The integrated system included:

- Zone 1/21 and Division 1 certified, explosion-proof 4G/ LTE Android Smart-Ex® 01 smartphone with ecom front and rear camera

- Push-to-Talk-over-Cellular Application (PTToC) of ecom partner TASSTA

- A cloud video surveillance application from IVIDEON

- A mobile device management solution from MOBILOCK

In connection with the control center, the mobile solution now functions as the infrastructure for the management of 3,000 filling stations and 400 trucks, with up to 500 fill-ups per day and 40 simultaneous filling operations. The entire process is monitored in the control center by six operators. The ATEX-certified Smartphone Smart-Ex® 01 supports mobile workers and enables the use of push-to-talk via LTE and Wi-Fi networks. This ensures the widest possible network coverage of all areas and situations – with low network latency, excellent data transfer rates and best voice quality. As the Smart-Ex® 01 has buttons, it can also be operated with gloves. No additional interaction with the smartphone is needed.

At a glance:

- Real-time communication between the individual operator and the control room

- Remote monitoring using real-time video streaming

- Control of single worker protection from the control room

- Automatic notification on entry and exit from the work areas